Egg hatchery humidification & humidity control

Nature does a great job in maintaining the correct conditions in order to hatch an egg. But in the artificial environment of a commercial egg hatchery it becomes the job of the hatchery manager to ensure all conditions are as perfect as they can be in order to ensure maximum yield of quality chicks from each batch of eggs. Not only are temperature and air flow critical but humidity also plays a crucial part in whole process.

Chick hatchery humidity levels

Pre-incubation storage: up to seven days 70-80%RH to reduce the risk of dehydration

Pre-incubation storage: over seven days 80-88%RH to reduce the risk of dehydration

Early Incubation: 50-60%RH to prevent excessive moisture loss resulting in dehydrated albumen and damaged embryo

Growth: 50-60%RH to allow the air space to develop to the correct size allowing chick’s lungs to develop correctly after internal pipping

Development: 50-60%RH to prevent wet navel and red hocks

Hatching: 50-60%RH to prevent shell sticking to down

Chick Pen and Broiler House first three days after hatching: 70%RH to prevent chicks dehydrating in the first few days after hatching

Benefits of Condair humidification in poultry farming include:

- Extensive expertise around the world in many farming applications

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide proven solutions for farming and agricultural processes

- Increased productivity with healthier birds

- Reduction in airborne dust

- Hygienic humidification systems with low operating costs proven in the industry

- Comprehensive service of expert advice, design, supply, installation, commissioning, maintenance and spares supply

Other industries where Condair delivers vital humidity control

Eliminating static with humidification

45-55%RH eliminates the build-up of static electricity in manufacturing environments.

Read moreMuseums, galleries, art & antiques humidification

Preserving works of art and antiques from the effects of dry air

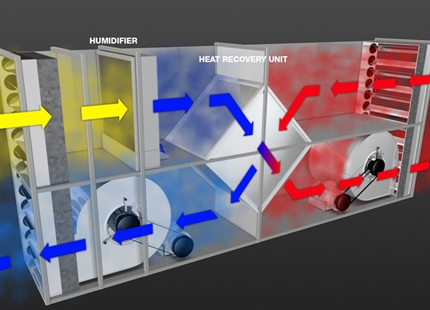

Read moreIn-duct evaporative cooling strategies

The three main AHU evaporative cooling strategies explained, covering direct, in-direct and exhaust air cooling.

Read moreData centre humidification

Provides high capacity, low cost evaporative cooling and combats ESD.

Read moreConcert halls & organs humidification

Preserving organs, protecting wooden instruments and auditoriums

Read moreOffice humidification

Improves health and productivity of staff and reduces absenteeism.

Read moreHospital & healthcare humidification

Reduces airborne virus transmission and improves patient health and recovery

Read moreHome humidification

Improves health and protects furniture, floors and textiles.

Read moreTea production humidification

Improves fermentation and produces blacker, higher value teas.

Read moreMushroom growing humidification

Provides optimal growing conditions and reduces Mushroom damage.

Read more