Humidification & humidity control

in tobacco production

Tobacco leaves, cut tobacco and paper are all extremely hygroscopic which means that they give up their moisture to the surrounding environment if the air is too dry. Dry air causes tobacco's properties to degrade resulting in shrinkage, weight loss, brittleness, flaking, splitting and tearing.

This causes tobacco to literally fall out of cigarettes, cigarette papers to misfeed on machines and cigar leaves to crack.

Maintaining the right level of ambient relative humidity prevents all these problems by ensuring that tobacco, paper and leaves retain moisture at the correct levels, so maintaining their quality and ensuring that production can proceed at full efficiency.

Recommended tobacco manufacturing humidity levels:

Primary production - 60-68%RH

Tobacco stores - 60-70%RH

Ripping rooms - 65%RH

Benefits of Condair humidification in the tobacco industry include:

- Extensive expertise around the world with many tobacco manufacturers

- Increased production efficiencies, reduced wastage, higher processing speeds

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide innovative custom solutions for unique processes

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

- BAT

- ITC

- Imperial Tobacco

- Rothmans International

- Gallagher + Co Ltd

- Swedish Match

- World Duty Free

- Altadis

- Hunters & Frankau

- West Indian Tobacco

- Rizla

Other industries where Condair delivers vital humidity control

Eliminating static with humidification

45-55%RH eliminates the build-up of static electricity in manufacturing environments.

Museums, galleries, art & antiques humidification

Preserving works of art and antiques from the effects of dry air

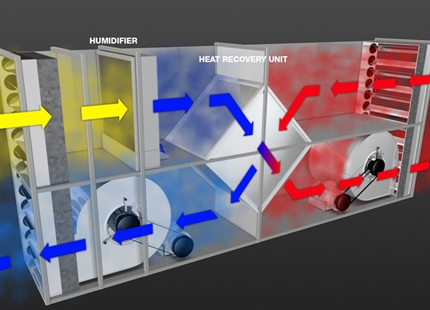

In-duct evaporative cooling strategies

The three main AHU evaporative cooling strategies explained, covering direct, in-direct and exhaust air cooling.

Data centre humidification

Provides high capacity, low cost evaporative cooling and combats ESD.

Concert halls & organs humidification

Preserving organs, protecting wooden instruments and auditoriums

Office humidification

Improves health and productivity of staff and reduces absenteeism.

Hospital & healthcare humidification

Reduces airborne virus transmission and improves patient health and recovery

Home humidification

Improves health and protects furniture, floors and textiles.

Tea production humidification

Improves fermentation and produces blacker, higher value teas.

Mushroom growing humidification

Provides optimal growing conditions and reduces Mushroom damage.