Increasing productivity

Correct humidity levels will improve productivity in several areas within an automotive manufacturing facility.

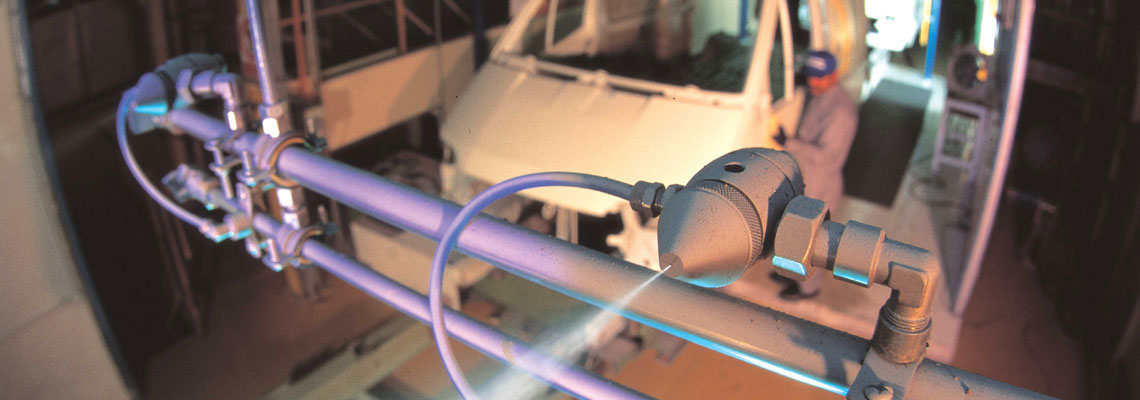

Paint spray booths

The optimum humidity for the transfer of paint from the spray nozzle to bodywork is 72%RH. At this level evaporation of the paint is reduced allowing it to reach the bodywork as the manufacturer intended. Reducing moisture evaporation from the paint also reduces the amount of paint dust that is introduced to the spray booth.

Sanding decks

By maintaining 55% relative humidity in sanding decks, dust is suppressed and static build-up reduced. This prevents airborne paint dust from being attracted to the surface of the bodywork, greatly decreasing sanding time and improving the quality of the finish.

Engine testing cells

Exhaust emission testing must be carried out within certain temperature and humidity ranges so it is important humidification systems can meet the control tolerance and provide reliable humidification.

Benefits of Condair humidification in the automotive industry include:

- Extensive expertise around the world with many automotive manufacturers

- Increased production efficiencies

- Comprehensive product range to precisely meet customers' requirements

- Ability to provide innovative custom solutions for unique processes

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

You may also be interested in...

Condair ME evaporative humidifier & cooler

The Condair ME provides low energy humidity control and evaporative cooling to an air handling unit or duct. Its innovative ...

Read moreJetSpray compressed air & water spray humidifier

Robust operation without the need for RO water. Compressed air ensures very rapid evaporation without the risk of drips.

Read moreCondair evaporative humidification at Jaguar Land Rover

Evaporative humidifiers maintain the humidity in the rolling road test cells at Jaguar Land Rover, Solihull, UK.

Read moreJetSpray at Aston Martin

Condair’s UK distributor, JS Humidifiers, has installed JetSpray humidification systems into the finishing areas at Aston Ma...

Read more